Meter Valves Manufacturer

Home / Meter Valves

Taher Brothers is a popular Meter Valve Manufacturer in Kolkata, West Bengal, Odisha, Bihar, Jharkhand & all over India in the market. We provide many types of Meter Valve. The gas Meter Valve is held attached to a piston that is held close by a spring. a fuel meter valve passes a small amount of fluid when there is no force or breaks on the pedal. The piston opens the valve and pressurized fluid is sent to the front callipers by Swagelok Meter Valve. On commercial sites such as shower rooms, campsites, and locker rooms Meter Shower Valves are used. They automatically shut off after each use and come on when the push button is handled. Meter Fuel Valve is another type of valve that measures liquid fuel to the gas used in a turbine during steady state operation and deceleration.

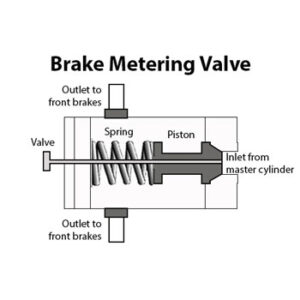

Similarly, Meter Air Valve features a non-hold open push button. When the push button has been pushed the air in the diaphragm is forced through the tubes. The air then opens the Air Meter Valve that allows the water to flow through the fixture. Meter Valve Brakes are used to balance the braking force. The valve holds back fluid in the front brake until pressure overcomes the return spring back to the rear drum. When precise flow control is needed Gf Meter Valve is used as it provides a linear flow curve. Hydraulic Meter Valve is a bit different since it provides free flow in one direction and metered flow in the reverse direction.

Chemical Meter Valve assists in receiving real-time positive displacement injection feedback along with the capability to house up 2 hydraulic cores. Water Meter Valve has an automatic cleaning cycle that flushes elements that are potential containment. Caleffi Flow Meter has a ball valve for flow rate setting and offers a direct reading of flow rate.

What Is Meter Valve ?

Valves available in the market are used for various purposes and are made up of different materials. Meter Valve is one such valve that is used for balancing the braking force. Flow Meter Valves has a precision tapered valve stem that accurately controls the flow. Meter valve Manufacturer in Kolkata, West Bengal, Odisha, Bihar, Jharkhand & all over India construct this valve mostly using brass or 316 SS forged bodies. Meter Ball Valves have a positive handle stop that prevents over tightening. Water Meter Check Valves allow the flow of fluid only in one direction and are hence also known as one way valves.

Specification List Meter Ball Valve

| BRAND NAME | Taher Brothers |

| SIZE | 1/2″ TO 4″ |

| THREAD | NPT, BSPP, BSPT |

| CONNECTION | THREADED, FLANGE END |

| FLANGE CLASS | 150#, 300#, 600#, 900#, 1500#, 2500# |

| PRESSURE RATING | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI |

| MATERIAL | SS 316, SS 304, SS 316 TI, COPPER, BRASS, DUPLEX, CS, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L, TITANIUM & ALL OTHER ALLOYS |

Gas Meter Valve Function

The Braking Powers are adjusted via a brake meter valve. It is the same as found on vehicles equipped with front plate and raise drum brakes. The meter valve prevents fluids from entering the front brakes until sufficient pressure is applied to overcome the return springs inside the lift drums. It is also known as a “meter block.”

Low Pressure Meter Valve(S, M, And L Series) Technical Data

Quick Links

- Cock Valves Manufacturer

- Stainless Steel Trap Manufacturer

- Bronze Valve Manufacturer

- Cast Iron Valve Manufacturer

- Bucket Valve Manufacturer

- Forged Steel Valve Manufacturer

- CI Water Meters Manufacturer

- Safety Valves Manufacturer

- Meter Valves Manufacturer

- Ball Valves Manufacturer

- Blow Down Valves Manufacturer

- Hydrant Valves Manufacturer

- Check Valves Manufacturer

- DRP Valves Manufacturer

- Globe Valves Manufacturer

- Gate Valves Manufacturer

- Diaphragm Valves Manufacturer

- Butterfly Valves Manufacturer

| End Connections | Dimensions, in.0 (mm) | ||||||

| Inlet/Outlet | Size | A | B | D | E | G | N |

| L series straight pattern | |||||||

tube fittings | 1/4 in.0 |

2.082 (71.06) | 2.034 (59.04) |

— |

1.013 |

0.058 |

1.026 |

| 3/8 in.0 | 2.046 (62.05) | ||||||

| 6 mm | 2.034 (59.04) | ||||||

| Male NPT | 1/4 in.0 | 2.000 (50.08) | |||||

| S series angle pattern | |||||||

tube fittings | 1/16 in.0 | 3.022 (81.08) | 0.081 (20.06) | 0.088 (22.04) |

0.038 |

0.045 |

0.092 |

| 1/8 in.0 | 3.032 (84.03) | 0.098 (24.09) | |||||

| 1/4 in.0 | 3.036 (85.03) | 1.002 (25.09) | |||||

| 3 mm | 3.032 (84.03) | 0.098 (24.09) | 0.099 (25.01) | ||||

| Male NPT/ tube fitting |

1/8 in.0 |

3.007 (78.00) |

0.098 (24.09) | ||||

| S series straight pattern | |||||||

tube fittings | 1/16 in.0 |

2.034 (59.04) | 1.056 (39.06) |

— |

0.038 |

0.045 |

0.092 |

| 1/8 in.0 | 1.090 (48.03) | ||||||

| 1/4 in.0 | 2.004 (51.08) | ||||||

| 3 mm | 1.090 (48.03) | ||||||

| 6 mm | 2.004 (51.08) | ||||||

| Male VCR fittings | 1/4 in.0 | 2.006 (52.03) | |||||

| M series angle pattern | |||||||

tube fittings | 1/8 in.0 | 3.030 (83.08) | 1.001 (25.07) |

0.050 |

0.058 |

1.007 | |

| 1/4 in.0 | 3.039 (86.01) | 1.010 (27.09) | |||||

| 3 mm | 3.030 (83.08) | 1.001 (25.07) | |||||

| 6 mm | 3.039 (86.01) | 1.010 (27.09) | |||||

| Male NPT | 1/8 in.0 | 3.004 (77.02) | 0.075 (19.01) | ||||

| 1/4 in.0 | 3.027 (83.01) | 0.098 (24.09) | 1.002 (25.09) | ||||

| Male NPT/ tube fitting |

1/8 in.0 |

3.004 (77.02) |

1.001 (25.07) |

0.075 (19.01) | |||

| Female NPT | 1/8 in.0 | 3.026 (82.08) | 0.097 (24.06) | ||||

| M series straight pattern | |||||||

tube fittings | 1/8 in.0 |

2.078 (70.06) | 2.002 (51.03) |

— |

0.050 |

0.058 |

1.056 |

| 1/4 in.0 | 2.020 (55.09) | ||||||

| 3 mm | 2.002 (51.03) | ||||||

| 6 mm | 2.020 (55.09) | ||||||

| Male NPT | 1/8 in.0 | 1.050 (38.01) | |||||

| 1/4 in.0 | 1.096 (49.08) | ||||||

| Female NPT | 1/8 in.0 | 1.094 (49.03) | |||||

| Male VCR fittings | 1/4 in.0 | 2.006 (52.03) | |||||

| L series angle pattern | |||||||

| tube fittings | 1/4 in.0 |

3.077 (95.08) |

1.017 (29.07) | 1.013 (28.07) | 0.058 (14.07) | 1.004 (26.04) | |

| 6 mm | |||||||

| End Connections | Dimensions, in.0 (mm) | |||||||

| Type | Size | A | B | B1 | B2 | C | D | H |

| 31 series | ||||||||

Female NPT | 1/8 in.0 | 2.000 (50.08) | 1.000 (25.04) |

0.091 |

1.000 |

1.028 (32.05) |

3.080 | |

| 1/4 in.0 | 2.006 (52.03) | 1.003 (26.02) | ||||||

| tube fitting | 1/4 in.0 | 2.040 (61.00) | 1.020 (30.05) | 1.016 (29.05) | 1.048 (37.06) | 1.054 (39.01) | 1.009 (27.07) | 3.060 (91.04) |

| 6 mm | ||||||||

High Pressure Meter Valve(31 Series) Features

- Straight and angle patterns

- 316 SS bar stock body

- orifice of 0.062 in. (1.6 mm), Flow coefficient of 0.04

- 2° stem taper (included angle)

- Metal-to-metal shutoff

- Round phenolic handle

- Panel mounting

Meter Valve Brakes

Hydraulic Meter Valve Pressure-Temperature Ratings

| Material Name | 316 SS |

| Material Group | 2.2 |

| ASME Class | 2080 |

| Temperature, °F (°C) | Working Pressure, psig (bar) |

| 200 (93) | 4295 (295) |

| –65 (–53) to 100 (37) | 5000 (344) |

| 400 (204) | 3560 (245) |

| 300 (148) | 3875 (266) |

| 500 (260) | 3310 (228) |

| 450 (232) | 3435 (236) |

| 650 (343) | 3080 (212) |

| 850 (454) | 2815 (193) |

| 600 (315) | 3130 (215) |

| 750 (398) | 2930 (201) |

| 700 (371) | 3000 (206) |

| 800 (426) | 2880 (198) |

Shortest delivery time in Chemical Meter Valve, View updated Parker Meter Shower Valve Price

Features Of Water Meter Valve

- available separately as valve body, or completely mounted with block as linear valve

- self-cleaning by O-ring design

- resistant to dirt compared to needle valve

- high service life owing to sintered body

- sealing material NBR

- brass with stainless steel design

- counter-clockwise closure

- leak-tight when closed

Low-Pressure Valves (S, M, and L Series)

Component | Valve Body Materials | ||

| Brass | 316 SS | ||

| Material Grade/ASTM Specification | |||

| 1b | Handle | Green anodized aluminum 6061-T651/B211 | |

| Handle screw | Black oxide and light oil-coated alloy steel/ANSI 18.3 | ||

| 1a | Handle | Silver-mist chrome-plated brass 360/B16 | 300 SS/A276 |

| Handle screw Lock screw➀ | Black oxide and light oil-coated alloy steel/ANSI 18.3 | ||

| 3 Bonnet sleeve | Sintered 316 SS | ||

| 4 Bonnet | Silver-mist chrome-plated brass 345/B453 | 316 SS/A479 | |

| 2 Panel mount nut | Silver-mist chrome-plated brass 360/B16 | 316 SS/A479—S, M; 316 SS/B783—L | |

| 9 Body | Silver-mist chrome-plated brass 377/B283 | 316 SS/A182 | |

| Lubricants | Molybdenum disulfide-based; silicone-based | ||

| 6 Body extension➁ | Silver-mist chrome-plated brass 345/B453 | 316 SS/A479 | |

| 5 Stem guide ring | Glass-filled PTFE | ||

8 |

Stem |

S17400 SS/A564—S; 316 SS/A479—M, L | Hard chrome-plated S17400 SS/A564—S; Hard chrome-plated 316 SS/A479—M, L |

| O-rings | Buna N | Fluorocarbon FKM | |

| 7 Body seal➂ | Buna N | Fluorocarbon FKM | |

High-Pressure Valves (31 Series)

Component | Material Grade/ ASTM Specification | |

| Packing nut |

316 SS/A276 | |

| Upper gland | ||

| Handle | Phenolic/D4617 | |

| Set screw | Nickel-cadmium plated steel | |

| Lower gland | 316 SS/A276 | |

| Bonnet |

316 SS/A479 | |

| Body | ||

| Packing | PTFE/D1710 | |

| Panel nut | 316 SS/B783 | |

| Stem | 440C SS/A276 | |

| Union nut | 316 SS/A276 | |

| Lubricant | Nickel antiseize with hydrocarbon carrier | |

- Application Of Parker Meter Valve

- Fine meter for wet process tools, cluster tools and other critical dispense applications

- Very high resolution meter control for both fluid and most gases

- Semiconductor and instrumentation

Flow Data Of Swagelok Meter Valve

S Series

| Pressure Drop to Atmosphere psi (bar) |

Water Flow |

Air Flow std ft3/min (std L/min) |

| 10 (0.068) | 0.001 (0.003) | 0.004 (1.01) |

| 50 (3.04) | 0.002 (0.007) | 0.010 (2.08) |

| 100 (6.08) | 0.004 (0.015) | 0.020 (5.06) |

M Series

| Pressure Drop to Atmosphere psi (bar) | Water Flow U.S. gal/min (L/min) |

Air Flow std ft3/min (std L/min) |

| 10 (0.068) | 0.009 (0.034) | 0.033 (9.03) |

| 50 (3.04) | 0.021 (0.079) | 0.090 (25.04) |

| 100 (6.08) | 0.030 (1.01) | 1.05 (42.04) |

L Series

| Pressure Drop to Atmosphere psi (bar) | Water Flow U.S. gal/min (L/min) |

Air Flow std ft3/min (std L/min) |

| 10 (0.068) | 0.051 (1.09) | 2.00 (56.06) |

| 50 (3.04) | 1.02 (4.05) | 6.04 (181) |

| 100 (6.08) | 1.07 (6.04) | 11.04 (323) |

31 series

| Pressure Drop to Atmosphere psi (bar) |

Water Flow |

Air Flow std ft3/min (std L/min) |

| 10 (0.068) | 0.012 (0.045) | 0.045 (12.07) |

| 50 (3.04) | 0.028 (1.00) | 1.02 (33.09) |

| 100 (6.08) | 0.040 (1.05) | 2.01 (59.04) |