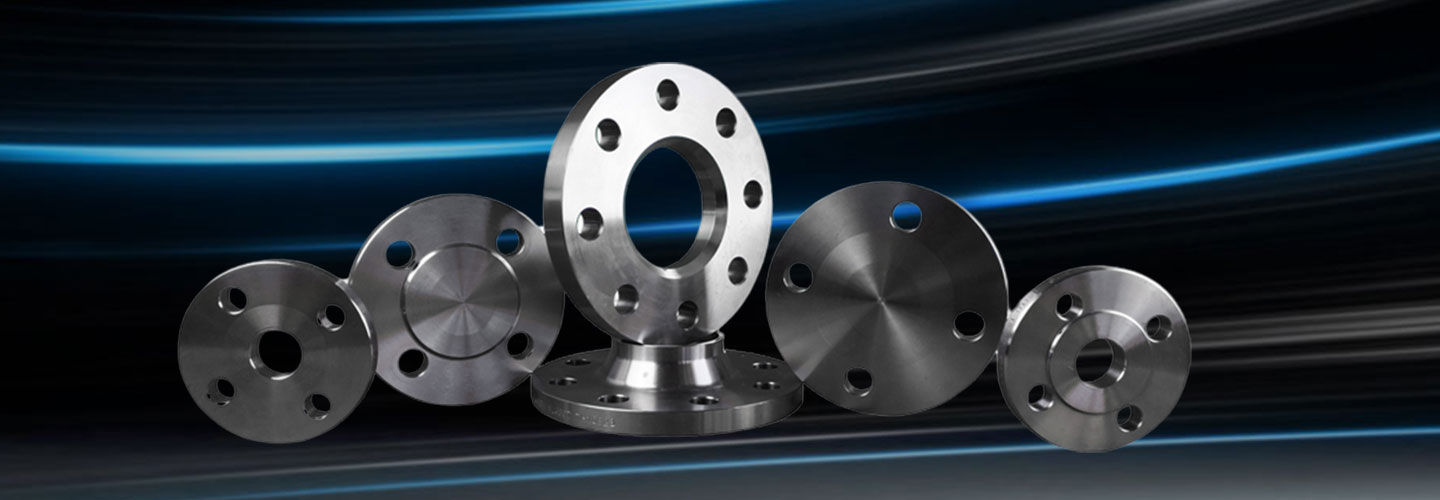

Branch Outlets Manufacturer

Home / Branch Outlets

Pipes need to be branched into different directions or the flow sometimes needs to be separated from the main flow. For this purpose, we require an outlet, through which the flow from the main pipe can be diverged to be connected to a branch pipe having the same size as the former or with a smaller bore size. Out of the available outlets, the Branch outlets prove to perform this function excellently, with added benefits. The Branch outlets be connected to the main pipe by just boring a hole in the main pipe, at the site from where you want the flow to be diverted and then attaching the Branch outlets of the suitable diameter. After fitting the outlet into the main pipe, the branch pipe is then connected through this outlet, and the flow is successfully branched in a different direction. Branch outlets can, therefore, be considered to possess dual functionality, that is, they play the role of a conjugating fitting while also diverting the flow into a different direction without disrupting the current flow. Taher Brothers is a Branch outlets Manufacturer in Kolkata, West Bengal, Odisha, Bihar, Jharkhand & all over India.

Branch outlets form an important unit of the entire complex piping system which are both connected to the main pipe as well as the branching pipe. Hence, it is unquestionable that the outlet also interacts with the liquid or gaseous components within the pipes which could in turn be corrosive. To prevent the outlets from corroding, they are equipped with anti-corrosion properties which enable them to resist corrosion caused by liquids or gases. Temperature fluctuations are also a major norm in several industries and which is skilfully tackled by the heat resistance property displayed by the branch outlets, due to which they retain their stability even when the temperatures far exceed normal operating conditions. Apart from the different resistances they display, the Branch outlets are known for exhibiting impressive strength, durability, and stability.

The plethora of properties attributed to Branch outlets has garnered their applications in industries such as the chemical industry, fertilizer industry, power generation, petrochemical, paper and pulp industry, oil and gas processing, food processing, water supply system, etc.

Stock Size Range and Specifications For Branch Outlets

Specification : ASTM A182 / B564 / B462 / A105 / A350.

Dimension Standard : ANSI/ASME B16.11, B 16.28 MSS-SP-43, JIS B2313, JIS B2312 etc.

Standard : ANSI, ASME, BS, DIN, EN etc.

Size : ⅛” NB – 4” NB (DN6~DN100)

Class / Pressure : 3000 LBS, 6000 LBS, 9000 LBS ( 1000 PSI – 15000 Psi ) etc.

Connection Type: BSP, BSPT, NPT

Stainless Steel Threaded Branch Outlets : 304, 304L, 304H, 310s, 316, 316L, 316H, 316Ti, 317/317L, 321/321H, 347/347H, 904L, 446.

Duplex Steel Threaded Branch Outlets : S31803 F51, S32205 F60.

Super Duplex Steel Threaded Branch Outlets : S32750, S32760.

Carbon Steel Threaded Branch Outlets : A105, LF2, IS 2062, F42, F46, F52, F60, F65, F70.

Alloy Steel Threaded Branch Outlets : F1, F5, F9, F11, F12, F22, F91.

High Nickel Alloy Branch Outlets : 200, 201, 400, K500, 600, 601, 625, 718, 800, 825, C22, C276, B2, X.

Alloy 20 Threaded Branch Outlets : Alloy 20.

Branch Outlets Application Industries

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulp & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry

Quick Links

- Nippolet Pipe Fittings Manufacturer

- Latrolet Manufacturer

- Threadolet Manufacturer

- Sockolet Manufacturer

- Sweepolet Manufacturer

- Nipolet Manufacturer

- Elbolet Manufacturer

- Weldolet Manufacturer

- Pipe Bushing Manufacturer

- Socket Weld Fittings Manufacturer

- Pipe Fittings Plug Manufacturer

- Pipe Fittings Plug Manufacturer

- Bronze Pipe Fittings Manufacturer

- Stainless Steel Pipe Fittings Manufacturer

- Weldolet Pipe Fittings Manufacturer

- Sockolet Pipe Fittings Manufacturer

- Forged Fittings Manufacturer

- Union Pipe Fittings Manufacturer

- Reducing Pipe Fittings Manufacturer

- Long Screw Pipe Fittings Manufacturer

- Jumnut Pipe Fittings Manufacturer

- Hose Connector Pipe Fittings Manufacturer

- Cross Pipe Fittings Manufacturer

- Boiler Mounting & Pipe Fitting Manufacturer

- Bell Mouth Pipe Fittings Manufacturer

- Tube Fittings Manufacturer

- Alloy Steel Pipe Fittings Manufacturer

- Carbon Steel Pipe Fittings Manufacturer

- Mild Steel Pipe Fittings Manufacturer

- Gi Pipe Fittings Manufacturer

- Branch Outlets Manufacturer

- Buttweld Fittings Manufacturer