Reducing Flanges Manufacturer

Home / Reducing Flanges

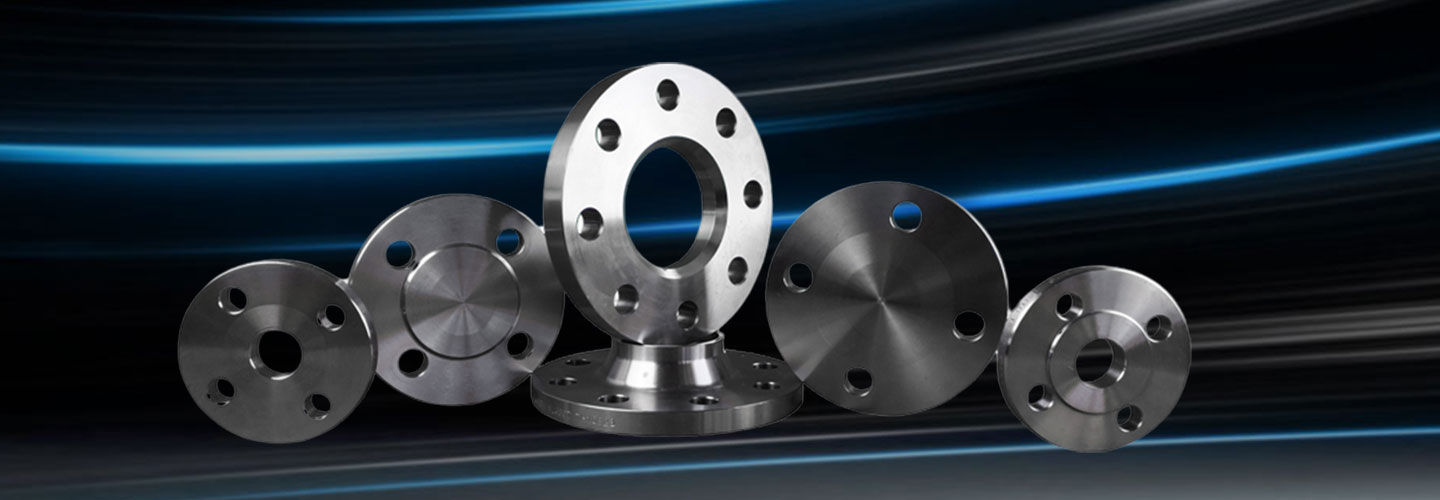

Reducing flanges are efficient and reliable components used in piping systems for joining and connecting pipes of different sizes. They are manufactured with precision and are easy to install. Taher Brothers is a reputed Reducing Flanges Manufacturer in Kolkata, West Bengal, Odisha, Bihar, Jharkhand & all over India known for its quality products. The flanges are made with superior quality raw material and have numerous features.

Features

- Excellent tensile strength

- Highly durable

- Rust resistance

- Corrosion resistant

- High temperature tolerance

Specification

- Size: 1/2″ to 72″

- Standard: ANSI B16.5, ANSI B16.47, MSS SP44, BS 4504, DIN2576, DIN2573, DIN2543, DIN2544, DIN2545, JIS B2220, UNI 2276, UNI 2277, UNI6083, UNI 6084, etc.

- Pressure Ratings: Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500

- Material: Stainless Steel, Carbon Steel, Alloy Steel, Duplex, Super Duplex, Nickel Alloys, Monel, Inconel, Hastelloy, Copper Alloys, Titanium Alloys, etc.

- Coating: Anti-rust Paint, Cold and Hot Dip Galvanized, Yellow Transparent, Zinc Plated, etc.

Reducing Flanges Standard Size and Specification

| Specifications | ASME B16.5 Reducing Flanges |

| Standards | ASME | BS | DIN | ANSI | GOST | EN |

| Pressure Classes | Cl 150, Class 300, Cl. 400, 600, Class 900, Cl 1500 and 2500 |

| Sizes | From 1/2 inch (i.e. 15 NB) upto 48 inch (i.e. 1200NB) |

| Face Type | FF, RF, LMF, SMF, RTJ, LJF. |

| JIS Standards | 5 K, 10K, 16K, 20 K, 30K, 40K, 63 K |

| UNI/ DIN / EN Standard | 6Bar, 10 Bar, 16Bar, 25 Bar, 40Bar |

Applications

Reducing Flanges are widely used in industrial, commercial, residential and automotive piping systems. They are suitable for use in the oil and gas industry, water treatment plants, and chemical processing applications.

Quality Assurance

The flanges manufactured by Taher Brothers are of the highest quality and are in compliance with international standards. The products are tested for quality and performance before they are shipped to customers.

Packaging and Delivery

The flanges are carefully packed and shipped to customers in strong and secure packaging. Delivery is prompt and reliable and customers can expect the products to arrive in good condition.

Quick Links

- Threaded Flanges Manufacturer

- SORF Flange Manufacturer

- Spectacle Flange Manufacturer

- Clamp Flange Manufacturer

- Sprinkler Flange Manufacturer

- Pressure Flange Manufacturer

- MS Angle Flange Manufacturer

- Hose Box Flange Manufacturer

- GM Flange Manufacturer

- GI Flange Manufacturer

- Fire Brigade Manufacturer

- Diary Fittings Flange Manufacturer

- CS Flange Manufacturer

- AS Flange Manufacturer

- Weld Neck Flanges Manufacturer

- Forged Flanges Manufacturer

- Spades & Ring Manufacturer

- Socket Weld Flanges Manufacturer

- Slip On Flanges Manufacturer

- Screwed Flanges Manufacturer

- Ring Type Joint Flanges Manufacturer

- Reducing Flanges Manufacturer

- Long Neck Weld Flanges Manufacturer

- Lap Joint Flanges Manufacturer

- High Hub Blinds Flanges Manufacturer

- Flat Flange Manufacturer

- Expander Flange Manufacturer

- Blind Flange Manufacturer

- Plate Flanges Manufacturer